|

|

|

|

|

|

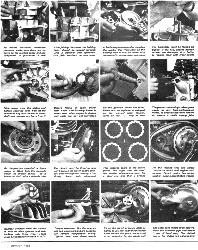

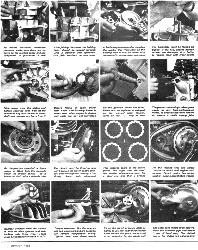

| View the 28 step rebuild procedure |

GRIFFON 250 REBUILD

REPRINTED FROM "MOTORCYCLE MECHANICS " OCTOBER 1969

John Milward of Greeves assembles a race winner!The Motorcycle Mechanics/Casrol 100 Mile Scramble was won by Greeves "Griffon" machines! The "A" team took first place and the "B" team clinched It by taking second.

Considering the opposition, this was no mean achievement and further proof of the high quality products of this all-British manufacturer.

Greeves make everything themselves - they even do their own die-casting for the crankcases at the Thundersley factory and their frames are famous throughout the world.

We went along to watch John Milward, the service manager, rebuild the 56C engine ...

The only special tools used during this rebuild were the flywheel holding tool and the block which stops the engine sprocket and clutch from turning while tightening their respective nuts.

Extensive use was made of Loctite, as one would expect on a high revving competition machine on which the winner's ''gold" might depend on all the nuts staying tight.

Other necessary equipment - if you are competing seriously - is a dial gauge for setting ignition timing accurately and a torque wrench to avoid over stressing component parts.

USEFUL DATA

The sparking Plug gap is 25 thou and Points gap 16 thou. Spark timing is 4 mm. btdc or 157.5 in. Carburation is by Amal 900 series Concentric. 32 mm. bore. Main jet 310. Pilot jet 25 and needle jet 106. The slide is No. 3 and needle should be in middle position.

The engine has a bore and stroke of 70 mm. x 64 mm. with a compression ratio of 11:1.

Transmission is by four speed. foot operated gearbox with duplex primary drive through an all metal 14-plate clutch.

Lubrication is by petroil mixture. The gearbox holds 3/4 imp. pint Shell Super "M". The primary case holds 1/2 imp. pint of Shell SAE 10 or 20.

The clutch, although of unconventional design, is a very robust unit and simple to work on once understood.

It consists of 14 metal plates, seven of which are steel and seven phosphor-bronze.

The clutch Centre goes through the clutch bearing - hence the need to fit the whole unit together to allow correct alignment.

Given a reasonable tool-kit, the average club rider should have no difficulty in stripping and rebuilding the "Griffon" .